Electrical Discharge Machining

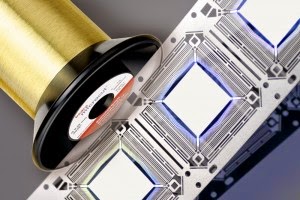

Electrical discharge machining or EDM is a machining

method that is mainly used for hard metals and other materials wherein the

application traditional machining techniques is impossible or very difficult.

Unlike traditional techniques, EDM can cut through

pre-hardened materials such as steel without needing heat treatment to soften

the material and then letting it re-harden afterwards. This makes EDM a very

efficient method of machining.

EDM is grouped along water jet cutting, laser cutting and

electrochemical machining as non-traditional machining processes.

If you want to find out more about EDM, you can visit the Wikipedia page or alternatively, visit and send an inquiry to Skarpverktyg.se.

Skarpverktyg AB

Skarpverktyg AB is the current market leader in Sweden for

wear parts, accessories and wires for EDM machines . The company represents

Berkenhoff, one of the largest manufacturer of EDM wires in the world.

Skarpvertyg is also an official distributor for Formann + Hummel, a

world-leading manufacturer of filter and filter systems.

The company was founded in 1981 and first started off as

a manufacturer of diamond tools and then expanded as an intermediary for some

of the best precision tool makers across the globe. Skarpverktyg has since

stopped with manufacturing diamond tools and focused on representing luminary

companies in the precision tool industry such as Finzler and Cape Diamonds.

The company boast a complete range of electrode materials

for sinker EDM such as graphite, copper, tungsten copper, electrodes and other

accessories. Skarpverktyg also provides clients with lenses, mirrors and beam

delivery systems from ULO Optics to all CO2 laser machines.

Today, Skarpverktyg AB has become a reliable name for

outfitting mechanical workshops with everything from clamping accessories for EDM

and laser machines.